By / Steve Clayman

Saving energy has become the defining term as we experience various governments’ requirements to reduce the use of fossil fuels. To underscore this trend, we are witness to different approaches on how to design buildings so that their respective energy demands are not only reduced, but can return excess energy to the grid. Let’s take a look at some of the dominant designations that reflect these trends:

- Passive House: a voluntary standard for energy efficiency in a building.

- LEED: Leadership in Energy and Environmental Design – a green building certification program.

- Carbon-neutral: achieving net-zero carbon dioxide emissions.

- Energy Star: 15% more energy efficient than the current Ontario Building Code

- Toronto Green Standard

- BC Energy Step Code

Note: There is considerably more information and more programs available online.

In order to fulfill the overall goal of reducing energy demand and lowering carbon emissions, every aspect of a building’s design is reviewed to contribute to the overall net result. Not only does this include elements such as the envelope, windows, lighting, and HVAC, but also the eventual equipment that will go into a building. According to NRCan’s National Energy Use Data Base (oee.nrcan.gc.ca/corporate/statistics/neud/dpa/data_e/databases.cfm?attr=0) and Canada’s Energy Efficiency Act (nrcan.gc.ca/energy-efficiency/energy-efficiency-regulations/guide-canadas-energy-efficiency-regulations/6861), there are specific requirements for such items as printers, dishwashers, water heaters, and others. The Energy Star label indicates the compliant products.

The other area influencing building design is the International Living Future Institute (living-future.org) and The Red List. The Red List comprises hundreds of chemicals that are harmful to a person’s health and found in construction products. Consideration is given to the potential negative human health impacts during the raw material extraction process, manufacturing, installation, and eventual demolition.

Although The Red List doesn’t directly impact energy efficiency, it can restrict the use of those building materials made up of the restricted chemicals, which of course would include insulation—think formaldehyde and PVC.

The mention of “energy efficiency” throughout all of these design designations ranks highly, as it should. Unfortunately, any mention of mechanical insulation is conspicuously absent. MI may or may not be mentioned in the general HVAC category. Where there is reference to the National Energy Code for Buildings (NECB), one would have to dig for the sections on duct and pipe insulation, whereas a great deal of space is devoted to envelope, electrical, and other subtrades. Yet, MI is there, waiting to be brought to someone’s attention. Herein lies the problem (challenge?).

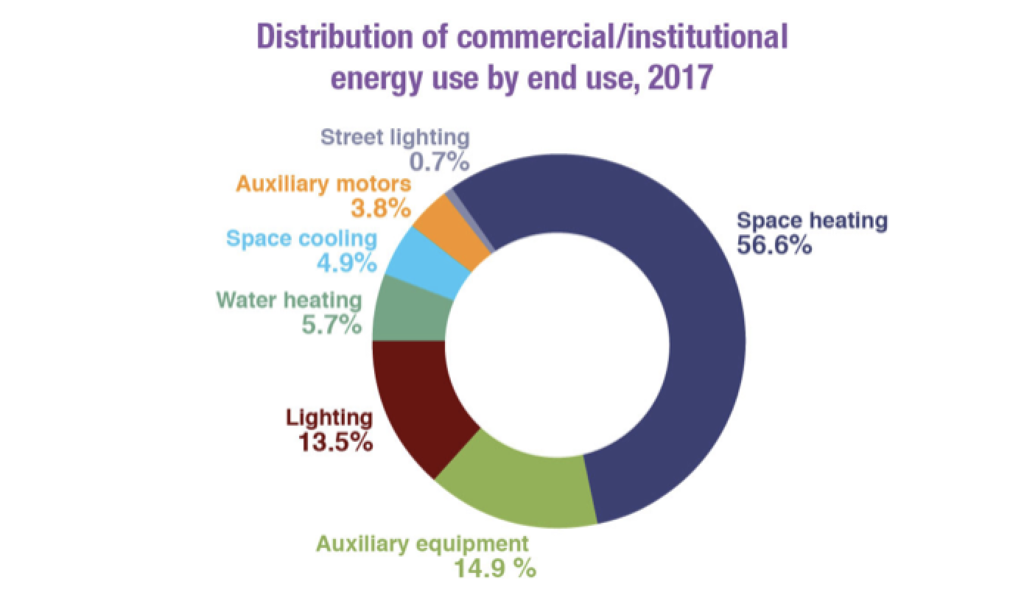

Again, referencing NRCan, the following is a graphic breakdown of energy use in Canada. Although the latest year available is 2017, the breakdown remains valid today. Adding “space cooling,” “water heating,” and “space heating,” the total percentage of energy use is 67.2%. That is the number where MI, correctly specified and installed, can contribute to the national goal to reduce energy consumption and GHGs.

Diagram courtesy of NRCan

To NRCan’s credit, every new edition of a code is followed with an instructional period with in-person meetings, webinars, and online instruction. This information is designed for architects, engineers, and other interested parties. The amount of time allocated for MI is debatable. Given the learning curve and available time required for all of the on-going energy saving regulations presents a formidable task. MI is somewhere in there, but where?

You’ll recall the increased minimum pipe insulation thicknesses published in NECB-2015. I’ll emphasize the word, “minimum” and come back to that in a bit. There is also the fine print as part of the tables, as well as the acceptable range of thermal conductivity results, operating temperatures, and mean temperatures. Should an application fall outside the allowable parameters, a separate calculation is strongly advised. At this point, the minimum thickness tables no long work.

For typical applications, such as high temperatures, high humidity conditions, outdoors installations, below grade installations, and below ambient conditions (I’ll say again; separate calculations) we rely on “3E Plus” (pipeinsulation.org) and the Mechanical Insulation Design Guide (MIDG) Calculator Tools (wbdg.org/guides-specifications/mechanical-insulation-design-guide/simple-calculators) to accurately arrive at the optimum (not necessarily the minimum) pipe or duct insulation thicknesses.

ASHRAE (ashrae.org) publishes the ASHRAE Handbook. Under “2020 HVAC Systems and Equipment” in the “Fundamentals” section is chapter 23 and “Insulation for Mechanical Systems”. There is great detail on MI in this area. As well, the National Mechanical Insulation Committee publishes the “Mechanical Insulation Design Guide” (wbdg.org/guides-specifications/mechanical-insulation-design-guide). Are mechanical engineers aware of the detail that’s available to them?

As demand on performance levels of various components increases, it makes no sense to allow for a scenario whereby insufficient pipe insulation thicknesses affect the efficiency of a boiler, a hot water piping system, or the delivery of conditioned air. There is a lot of “noise” out there with different segments of the construction industry clamoring for attention, “Pick me, pick me, I’ll save energy!”

This is the challenge for the MI industry. Make noise! The energy saving contribution offered by MI needs a platform and an audience. Mechanical engineering specifications have to be upgraded. MI specifications out for bid have to be scrutinized for accuracy relative to the design criteria and finally there is the challenge posed by ensuring quality installations, that is, third-party inspections. This places a significant responsibility on the MI industry to strongly advocate for itself by going in several directions with a compelling message. ▪