Project Volume and Scope Demand Collaboration

By / par Jessica Kirby

Photos by /par Shurfit Products

PARQ Casino is a six-storey casino next to BC Place in downtown Vancouver that includes gaming space in the main podium and three hotel towers, each off of a separate corner. The work was broken into three contracts – the podium, towers, and parkade – and there were multiple consultants and contractors on each, requiring an immense amount of collaboration, communication, and teamwork.

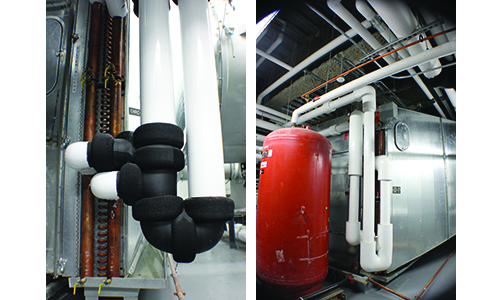

Justin Albertson, project manager for New Central Mechanical Insulation, insulation contractor on the project, said the specification called for elastomeric elbow covers, which were a welcome solution to inadequate coverage of these tricky areas.

Without these the product is sometimes loosely filled around the fittings, leading to inadequacies in thickness, he said. “Until now we would be wrapping elbows with multiple layers of blanket wrap, which takes time and you can’t guarantee the vapour barrier. Having these fittings able to mate directly to the elbow gives 100 percent contact and guarantees a properly insulated fitting.”

Another technical challenge solved included the use of pre-manufactured high-density pipe supports. “Before we would use a one-inch by one-inch by six-inch high density block and the quantity depended on the size of the pipe—we used three for 12-inch pipe, for example,” said Albertson.

In this scenario, depending on how the pipe was run and the number of elbows, a hanger could have a tremendous amount of weight and more high density blocks were required than the specified three, increasing labour and material. With high-density pro pipe supports it was possible to reduce base labour including the potential of the extra workload, adding extra high-density blocks, and redirect manpower even sooner.

“It was all about manpower and how to shave seconds to be able to move on to the next task,” said Albertson. “We would slide in the high-density supports with the shield already on it and attach the hanger, saving time for us and the plumbers.”

Manpower was a challenge on this project—as employment demographics shift, finding quality, skilled labour gets more difficult and this case was no different. At its peak there were ten installers onsite at once. The often short-staffed team worked six or seven days a week at ten-hour days to meet the 15-month timeline on the insulation scope.

Working downtown Vancouver is always tricky when it comes to space and laydown area, but general contractor Ellis Don managed to mitigate potential issues with scheduling deliveries to each of the three separate corners on the building.

One element of the project that stood out for Albertson was how invaluable it was frequently communicating with the other trades and the general contractor.

“We were always letting them know where we were at and where would soon be, making sure everyone, in every trade, was on the same page. It kept us all in lockstep to make sure we were progressing at the same pace.”

Albertson adds it was a phenomenal project success, despite the compressed timeline and overwhelming volume of work. “I don’t think it would have been as easy if the trades hadn’t been so open minded and willing to work together,” he said. “It was a great project to be part of.” ♣