By / Steve Clayman

Very little stands still, and the same holds true for energy codes. In Canada, national codes are published on a five-year cycle with corrections and addendums published in the interim. ASHRAE 90.1 is updated every three years. The process of updating codes actually begins a year or so prior to the issuance of the latest edition of any given code. As with so many things in life, there are sometimes exceptions.

Each cycle brings changes primarily designed to improve the overall energy efficiency of a building by a certain percentage. Changes may be related to the envelope, lighting, mechanical equipment, or a combination of several elements. Once the new editions of the National Energy Code of Canada for Buildings (NECB) and ASHRAE 90.1 are published, it takes some years for the consulting community and authorities having jurisdiction to catch up. The reason for this is because there is a learning curve that comes into play along with numerous projects designed and approved based on the then current code. We are seeing NECB-2011 and ASHRAE 90.1-2010 referenced in specifications.

In the case of NECB-2011, the follow-up edition was NECB-2015, which in turn was followed by the most current edition, NECB-2017. Certainly, an exception to the five-year traditional timeframe. This shorter time frame is indicative and how quickly the approach to energy conversation is changing. With ASHRAE 90.1, the most current edition is ASHRAE 90.1-2019.

On June 13, 2016, the National Research Council of Canada (NRCan) published an overview of NECB-2015 in which the following was stated: “Over 90 changes were introduced in the National Energy Code for Buildings 2015 NECB.” Among these 90-plus changes was, “Requirements relating to piping and duct insulation were made more stringent…” This change relating to mechanical insulation then carried into NECB-2019.

Let’s have a look at the impact NECB-2017 and ASHRAE 90.1-2019 will have on mechanical insulation.

NECB-2017

Pipe Insulation

NECB-2011 was the edition where most minimum pipe insulation thicknesses were increased substantially—some by as much as 50 percent. Although the table has “minimum” in its title, the reality is that these increased thicknesses are optimum thicknesses, verified by random 3E Plus calculations. This means we won’t be seeing any further increases in thickness, and NECB-2017 reflects this.

Then there’s the fine print where the new heart of the changes now lies. There are several. I’ll cite two for illustrative purposes. I should point out that no sooner was NECB-2017 published, that queries began coming in to NECB asking, “What does this really mean?” When enough of these queries accumulate, NECB publishes Intent Statements.

So, for NECB-2017, in 5.2.5.3.

Note 1) Except as provided in Sentences (2) to (4), piping forming part of an HVAC system shall be thermally insulated in accordance with Table 5.2.5.3. (See Note A-5.2.5.3.(1).

Intent Statement:

Provision: 5.2.5.3.(1)

Objective:

OE1

Attributions:

[F92, F93-OE1.1]

Intent(s)

Intent 1. To limit the probability that there will be insufficient insulation on piping in HVAC systems, which could lead to uncontrolled thermal losses or gains, which could lead to unnecessary consuption of energy for heating and cooling, which could lead to excessive use of energy, which could lead to an unacceptable effect on the environment.

Note 7) Insulation material required in Sentence (1) shall be installed in accordance with good practice. (See Note A 5.2.2.5.(7) and 5.2.5.3.(7).)

Intent Statement

Provision: 5.2.2.5.(7)

Objective:

OE1

Attributions

[F92, F93-kOE1.1]

Intent(s)

Intent 1. To limit the probability that insulation of air-handling ducts, plenums, and run-outs will be improperly installed, which could lead to inadequate performance of such insulation in HVAC systems, which could lead to uncontrolled thermal losses or gains, which could lead to unneccessary consumption of energy for heating and cooling, which could lead to excessive use of energy, which could lead to an unacceptable effect on the environment.

Duct Insulation

As for thermal duct insulation, Section 5.2.2.5. Duct and Plenum Insulation includes Table 5.2.2.5. Insulation of Ducts. This information remains unchanged from earlier editions of NECB. The insulation thickness is determined by using the temperature difference between the ambient and operating temperatures. Again, there is the fine print with exceptions and these should be noted.

Where are the Provinces and Territories?

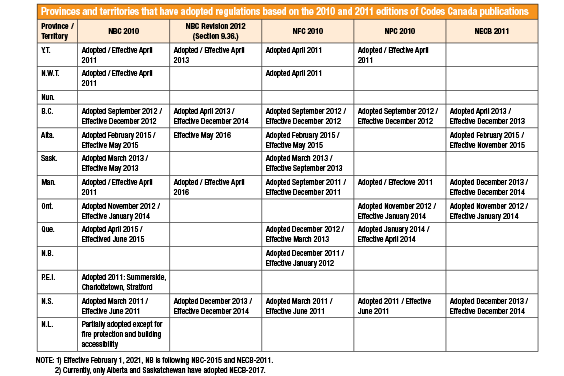

Provinces and territories have taken different positions on energy efficiency and where NECB fits in with their respective approaches to energy efficiency. The National Building Code (NBC), National Fire Code (NFC), and National Plumbing Code (NPC) are also included in this table (see below).

ASHRAE 90.1-2019

As with NECB-2017, pipe insulation thicknesses in ASHRAE 90.1-2019 haven’t increased since the ASHRAE 90.1-2010 edition and for the same reasons. Although the pipe insulation thicknesses in NECB are based on ASHRAE 90.1, there are a few differences:

- Nominal pipe sizes don’t completely align. In some instances, this changes the pipe insulation thickness.

- Some pipe insulation thicknesses in the section on Cooling Systems are greater in NECB-2017 than ASHRAE 90.1-2019.

- Of course, there’s always the fine print that “shall be” paid attention to.

Note: Some specifications call for either NECB or ASHRAE and some call for both, while stipulating that the code demonstrating the more stringent requirements is to be used.

Conclusion

If all of this looks like a potential minefield, that’s probably not too far from the truth. I understand the consultant’s responsibility in developing specifications, but sometimes the person with the ring gets it wrong. Sometimes the insulation contractor is asked for recommendations. In both cases (an incorrect specification or recommendations) it is incumbent upon the insulation contractor to make sure what is eventually installed is what the conditions require and not necessarily what is in the specification. In many cases, the insulation contractor is considered the expert in the trade.

This is particularly important when it comes to upgrades and retrofit work. If in doubt, ask a manufacturer for confirmation and then go on record with your conclusions.

Correctly specified and installed mechanical insulation works. Make it so.▪