ROCKWOOL’s proprietary CR-Tech™ corrosion inhibitor delivers 5x better corrosion mitigation to shield plant piping from the dangers and costs of corrosion

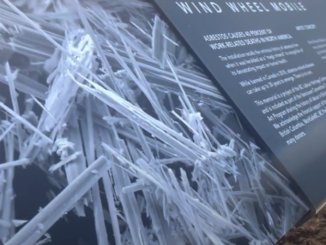

[Houston, Texas, March 6, 2024]—ROCKWOOL Technical Insulation has introduced its ProRox® PS 965 with CR-Tech (Corrosion-Resistant Technology), the industry’s first stone wool insulation with built-in corrosion inhibitor. The latest offering in the company’s stone wool insulation portfolio, the proprietary CR-Tech corrosion inhibitor shields plant piping against corrosion under insulation (CUI) by creating a protective barrier between the pipe’s outer wall and the insulation’s inner surface.

Water is a critical ingredient to CUI that finds its way into every type of insulation. When this water migrates through the insulation to reach the pipe’s metal surface, it often leads to aggressive corrosion, resulting in dangerous and costly heat losses, downtime, and leaks.

“CUI creates serious efficiency drains on a plant in the form of increased energy usage, major downtime, higher maintenance costs, and potentially hazardous leaks,” says Dan Aiken, Business Unit Director of Americas for ROCKWOOL Technical Insulation. “But with ProRox PS 965 with CR-Tech, CUI may have finally met its match.”

The next-generation CR-Tech corrosion inhibitor builds on ROCKWOOL’s 80-plus years of innovation in stone wool insulation to mitigate against the risks and costs of CUI. CR-Tech is embedded into the inner surface of ProRox PS 965 mandrel wound pipe sections, right where the insulation touches the pipe. When water reaches the inner insulation surface, the inhibitor activates to form a thin protective layer that shields the pipe from contact with water.

Proven corrosion protection and more

CR-Tech is combined with the proprietary, award-winning WR-TechTM (Water-Repellent Technology), which minimizes water absorption in the insulation. The result is a state-of-the-art solution that delivers:

- Superior corrosion protection and water repellency in one. The combination of CR-Tech and WR-Tech does more to keep pipes dry and better protected from CUI. In industry-standard testing like CUI test method ASTM G189, CR-Tech achieves 5X better corrosion mitigation than other hydrophobic insulation materials, even those with corrosion inhibitors.

- Robust, versatile performance beyond corrosion inhibition. ProRox PS 965 with CR-Tech boasts exceptional acoustic and thermal insulation properties for reduced energy consumption and utility costs, fewer emissions, and reduced health and safety impacts.

- Ease of installation. ProRox PS 965 with CR-Tech arrives at the plant in lightweight, robust hinged sections that install easily, thereby lowering material and handling costs.

“With the addition of WR-Tech, we’ve developed a pipe insulation technology that sets new performance benchmarks in CUI mitigation,” Aiken says. “This offers greater efficacy than other industrial insulation.”

For more information on the product, please visit rti.rockwool.com/crtech